Framing Methods in Mid-rise Timber Construction

Timber framing has been in use for centuries, with many famous examples still standing like Greensted Church in England, Urnes Stave Church in Norway, and Horyu-ji Temple in Japan. Of course, building techniques have changed quite a bit over time, and many modern structures now make use of light timber framing instead of the heavy timber framing prevalent in centuries past. Light framing uses smaller, repeating timber members fastened together with nails, screws, and bolts to pass gravity and lateral loads to the soils below.

Light timber framing (also known as light-frame construction) has many advantages, particularly for low- and mid-rise structures in the 1- to 6-storey range, including its flexibility, speed of construction, sustainability, and resiliency. The elements themselves are light enough for one person to carry around a job site or factory, and it is easily adapted to modular construction through panelization while still allowing for custom construction where panelization is not achievable. Timber is a natural carbon sink that absorbs carbon throughout its life, and it is sustainable and renewable when cultivated carefully, which is common practice in Canadian forests. On top of all that, light timber structures are capable of withstanding windstorms, hurricanes, and even earthquakes when built and detailed to do so!

Just like construction as a whole has evolved over time, so too has light timber framing. Balloon framing was popular in earlier timber structures, especially in the 1- to 2-storey range, but modern structures most commonly make use of platform framing. A hybrid approach, known as semi-balloon framing, utilizes the best parts of each technique to maximize their respective benefits.

Balloon Framing

In balloon framing, the studs in the walls continue from the ground to the roof and the floor joists are supported by a ledger (commonly notched into the studs). The roof joists or trusses bear directly on top of the wall. The walls get built first, followed by installing the ledger and landing floor joists.

The biggest advantage of balloon framing is how fast its construction is compared to the post and beam construction it typically displaced. Post and beam required high levels of very skilled carpenters to cut and assemble joints precisely, while balloon framing allowed for a smaller number of skill carpenters overseeing large teams to build much more quickly. Running the studs full height also limits shrinkage, helping to avoid cracking in plaster. A major shrinkage source in timber comes from cross-grain bearing, which is almost eliminated in balloon framing.

Balloon framing has almost entirely been supplanted by platform framing. The biggest driver for this is the difficulty in finding tall enough, straight enough lumber to build with. This also effectively eliminates its usage in larger structures since studs are simply not available in excess of 24’, and they are even quite rare at that length. Modern engineered lumber is now available in longer lengths, but they are still special order items. Fire is a larger risk with balloon framing than other methods due to the open hollows between floors. Fire blocking is typically required to limit how quickly fire can spread.

Platform Framing

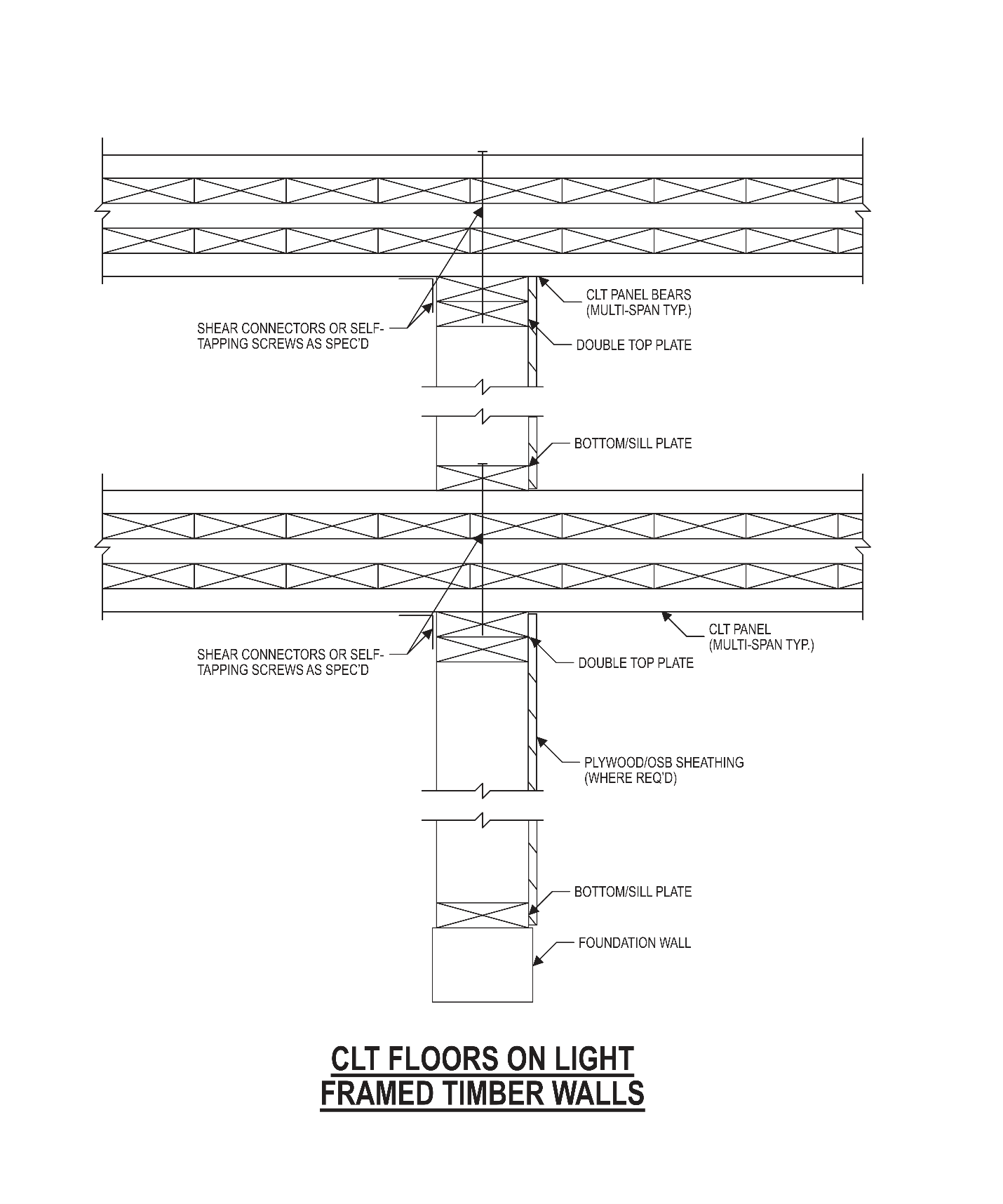

Platform framing is the most common timber framing method used today. The building is built one floor at a time, starting with the walls and then landing the joists directly on top of the wall top plate. This makes the largest member length much shorter, typically around 10’ for walls and 16’ for joists. Larger spans for joists can be easily achieved using engineered timber joists, such as I-joists, or mass timber floor systems such as cross laminated timber (CLT) panels.

The top of every wall has a double top plate that must burn through before fire spreads between floors. While wood is combustible, it has well established burn and char rates and has been readily codified to slow the spread of fire.

One of the most significant downsides of platform framing is shrinkage. Shorter structures do not get as heavily impacted, but 5- and 6-storey buildings can see upwards of 1 1/2” of shrinkage over their height without careful moisture control and detailing. This shrinkage can be accommodated, but detailing becomes critical where timber meets other materials, such as concrete, masonry, or steel. Without care and attention to these locations, issues may appear ranging from cracked drywall, difficulty opening windows, and sloped floors to damaged piping, damaged brick, or structural separations.

The other major downside of platform framing is primarily an issue in the 5- and 6-storey range. These mid-rise timber structures can see significant loads at the lower levels that must transfer through the joists and blocking. This is generally achievable but requires more significant blocking or rim joists than typically seen in low-rise residential construction.

Semi-Balloon Framing

The largest obstacles for balloon framing are long members and fire blocking, while the biggest challenges for platform framing are shrinkage and load transfer at floors. Semi-balloon framing tackles all four hurdles in one leap through the use of hangers. This method builds up floor-by-floor like platform framing, but lands joists onto top mount hangers on the top plates. The wall studs are typically less than 12’ long and easy to source while the double top plate minimizes fire spread. The hanger eliminates the majority of the shrinkage zone by putting only the plates in cross grain loading instead of the blocking and plates. In doing so, shrinkage can be as little as 1/4” or 3/8” for a building. The gravity and lateral load systems pass load more directly from wall above to wall below, eliminating heavier blocking at the lower levels and avoiding specific blocking details around holddowns and similar hardware.

Semi-balloon framing requires the use of hangers like those from Simpson Strong Tie or MiTek, which adds to the supply chain and cost. Placing these correctly on the walls can also be difficult since they need to align between adjacent bearing walls. However, the hangers can be ordered in large quantities and alignment tolerances are similar to those found in platform framing.

Mass Timber Flooring

Another system that tackles the hurdles from balloon and platform framing is the use of mass timber flooring systems like cross laminated timber (CLT) or nail laminated timber (NLT). These systems are built in large panels that span multiple bearing lines, so they bear directly on top plates of walls. They retain the major advantages of avoiding tall wall studs, fire spread, and load transfer. While CLT floors add a cross-grain bearing zone compared to semi-balloon framing, the shrinkage is still minimized relative to platform framing. CLT panels are typically more dimensionally stable and use relatively dry lumber constructed in factory, eliminating major moisture sources in the timber.